Boston

12MWe Biomass Project

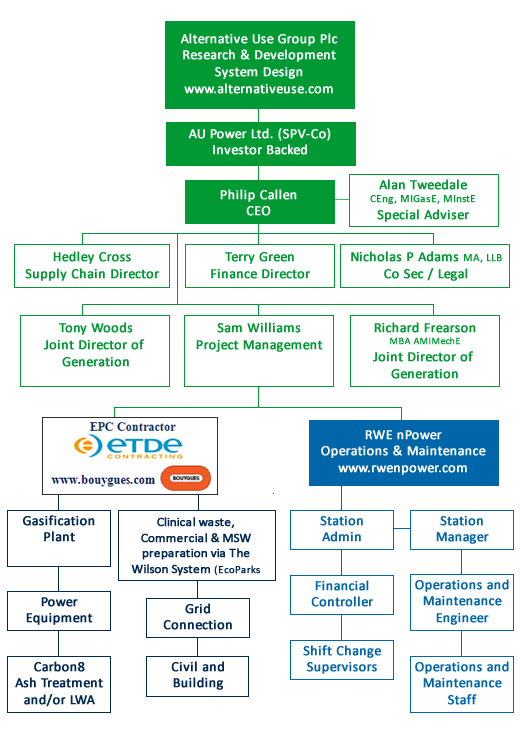

Management Structure

The Company Management together have

a broad experience which includes Technical Project

Management, generating plant operations and maintenance,

power and process plant construction and latterly,

electricity generation from biomass. With combined

worldwide employment of 190,000.

Philip Callen

CEO

Philip Callen, (PC) the General Manager of Alternative Use Group Plc is 64 years of age, has been married for 42 years and has 2 children and 4 grandchildren.

During his career he has had wide experience of business and industry in many fields, including waste collection and disposal.

During the 1990’s, having seen at first hand the problems of landfill disposal, and having reflected on the environmental and economic damage caused by traditional methods of waste disposal, he decided to devote himself to discovering an efficient, environmentally friendly and economic solution to the worldwide problems of waste disposal. He realised that the power generation industry was grappling with similar problems of exhausting natural resources, and by the traditional methods of generation contributing to global warming and dimming and the dire environmental consequences of those phenomena.

He, therefore, formed Alternative Use plc to research and develop a system that would be a solution to both problems at the same time. The concept of converting waste to energy by pyrolysis-gasification was not new, but there was no efficient, reliable or economic system. By investigating all available systems, and involving major worldwide manufacturers and suppliers, under PC’s guidance Alternative Use plc was able to develop a system that fulfils all the criteria and is approved by the most respected consultants, and to form a consortium of very major companies to manufacture and supply all the necessary components to support its implementation.

PC had for some years been troubled by the plight of underdeveloped countries and the fact that they were unable for lack of resources adequately to address environmental issues. His view has been that it will be by viable economic development, not by grant aid, that real sustainable development and actual poverty reduction will occur. On trips to Africa in connection with the business of Alternative Use plc he observed at first hand that the problem of waste disposal in that continent was growing out of control, with landfill the only solution being offered. He immediately realised that with the desire of such countries to embrace new technology and the lack of vested interests, the introduction of Alternative Use plc’s technology could rapidly introduce major benefits economically and environmentally in the waste disposal sector, and at the same time provide electrical power of which there is an almost universal shortage.

The system now being marketed by Alternative Use Group plc has been developed by PC and the team he has created to provide energy from waste systems that can be adapted for use in all parts of the world, and can deal with waste streams of any combustible composition, so that solutions can be provided to clients ranging from small private concerns to local, municipal and even national governments and major multi-national companies.

PC’s vision is to see energy from waste accepted as the normal way of solving the joint problems of excess waste and shortage of electrical power, and at the same time to ensure that the technology is as readily available in the third world as in the first so that the benefits of the systems of which he has overseen the development can play a major role in those countries where the need is greatest.

Alan Tweedale, CEng, MIGasE, MInstE

Special Adviser

Trained as a Gas Production Engineer and at 21 years of age was a Shift Engineer at the largest Gas Works in the North of England. During National Service commissioned as a Flying Officer and returned to the Gas Industry to manage the construction and commissioning of two Naptha Reformers and two Natural Gas Wells. Moved to the Coal Industry as Senior Fuel Technologist in Northumberland and Durham.

Joined Associated Heat Services (now Dalkia) and became Managing Director taking the Company to a full listing in 1982.

Commenced own Companies in 1984 and built 83 Coal Fired Energy Modules; Designed, built and operated two Waste Fired NFFO Contracts at Newcastle upon Tyne and IOW.

- The IOW Plant generated 2.0 MW and this has now been modified to accept an Energos gasification grate.

- The Newcastle Plant used 40,000 tonnes p/a of RDF, generated 2.3 MWe from a condensing turbine and 500 kW from a back pressure set, with the pass out steam heating 2,200 dwellings.

Designed and built a 4 MWe Waste Fired Plant in South Wales; handing this Plant over in June 2005.

In 1989, along with a partner, I acquired the shares of the NIFES Consultancy Group, and remained Chairman until 2006.

Whilst I have been responsible for the design and construction of a number of conventional waste fired steam and power plants, my main activity has been the long term operation of boiler, power and gas generation plants.

Formed Premier Energy Ltd in 2005 to provide advisory and design services to the Energy from Waste Industry. Recent work:

- Technical Advisor and proposal Evaluation - Laing Regen Energy Ltd (Wood Waste combustion and power generation).

- Energy Technology Institute (Loughborough University) - Independent Assessor for the Distributed Energy Programme.

- Provision of basic calculations: Material balance; Energy Output; Equipment suitability - Fairport Engineering Ltd.

- Technical Advisor, equipment Proposal Evaluation - Anglesey EcoPark (MSW/biomass/sewage sludge gasification).

- Design and procurement of upgraded flue gas treatment plant and new Fly Ash/Spent Lime pneumatic system and silo - Energos - (Commissioned 01.09.08)

Hedley Cross

Supply Chain Director

Principal Consultant with hedley.cross consulting

Associate Consultant with Hughenden Consulting

Associate Consultant with Informance

Business experience

24 years experience in food manufacturing and feed milling. A former Management Accountant with previous appointments ranging from Senior Accountant, Company Secretary, Managing Director of a Sign Making and stationery business, Supply Chain Manager and Projects Manager [Prince2].

In 2000 was appointed Supply Chain Manager for Padleys, heading Procurement, Operational Planning and Administration functions for the group. Following its take-over in 2004 I became Group Projects Manager and then Systems Architect for systems, process development, and business analysis for Moy Park, with a team of business analysts and external consultants.

Project Management Experience.

Project managed installation of a group wide ERP system[Prism], GW Padleys 1997-00

Project managed integration to Computerway MES GW Padleys 1997- 00

Project managed review and redevelopment of ERP[Protean] in Moy Park sites 2004-6

Project managed integration and replacement ERP system - all GB sites 2006-7.

Project managed MES integration (Computerway to Scanplant) - all GB sites2006-07

Project managed Marel [Innova] (yield reporting installation) in a GB site. 2008-09

Project managed integration/replacement ERP system – 2 Marfrig Europe sites 2009

Project managed Isys T&A system implementation Moy Park - Anwick site 2010

Installing integrated ERP’s into an organisation exposes its principal Project Manager to all the operational areas of the enterprise:

For those who may have less familiarity with ERPs, they are more than “Enterprise Resource Planning” implementations. Typically they cover Finance, Accounts Payable and Receivable, Costing, Customer Relationship Management, Manufacturing Schedules, Quality Assurance, Product Life Cycle Management, Asset management, Factory floor data capture and integration, Traceability, Despatching, BI Reporting, at all business levels - and also “Enterprise Resource Planning”. Successful implementations focus as much on people and processes as they do on the technologies. Streamlining an enterprise supply chain is about coordinating and optimising all of these key elements, following an integrated Sales and Operational Planning approach.

Last employer, for the last 20 years ending in July 2010: Moy Park Ltd: a division of the Marfrig Group. Moy Park has factories, in England, Northern Ireland, France and Holland generating c £1b turnover. It is an integrated poultry producer with its own breeder and grower farms across Lincs, Norfolk, Suffolk and NI; with hatcheries and mills, Primary and Further Processing Factories, and also its own Distribution fleet based in Lincolnshire.

Marfrig plc is an international food group with its HQ in Brazil and business interests worldwide. Moy Park is roughly 25% of the Marfrig group.

Education

Downham Market High School, Norwich School of Art, Norfolk College of Arts & Technology.

Qualifiactions

5 GCE O levels

4 RSAs

2 GCE A levels (Accounts, Economics)

HNC Business Studdis (dist)

ACCA level 1

ACIS finalist (registration now lapsed)

Married 30 years. Two boys. The eldest is a law graduate, the second commences degree studies on 2010. Wife, Lorna a qualified nurse.

Hobbies: An active interest in the Arts. I have a river boat moored in Lincoln marina.

Part of my Supply Chain responsibilities between 2000 and 2004 was to research all aspects of my employer’s core and dispersed costs, one major component of which of course being waste. It is during this research period I first met Phil Callen and Alternative Use.

Following initial feasibility studies we worked on a site based generation from waste unit. The concept utilised Waste/Fuel (effluent sludge edible and inedible offal, feathers leaf fat oils and blood etc) was exclusively generated on and by a single major primary processing site based in Lincolnshire. The source material could be conveyed directly into the fuel feed hopper of the power producing plant.

The unit could be located directly on site (or next door behind a separation wall, with a ‘pipe line’ between the two). The beauty of this solution was that it avoided all downstream logistics and land fill disposal, converting what was an escalating cost into a revenue stream. As the fuel source material was carried under cover as part of a continuous process the solution could be constructed to comply with current and predicted hygiene rules. The power from the waste plant could be highly attuned to the consistent daily waste materials supply.

As part of this I also experimented with an Archimedean screw compactor for feathers and fat. This reduced the water content and presented ‘slugs’ of material to the power plant hopper.

The engine/ turbine combination specification changed over the extended period as more was understood about this developing field. Toward the end of of the project we were reviewing emerging Gasification technologies.

The process proposed by Phil was clean, met with all Environmental Agency standards for emission controls. It used proven engineering with low risk and generated Green Energy.

Unfortunately the business for which I was engaged in ths project was then taken-over, and this project was shelved as the new company were already heavily engaged in a multi-million pound incinerator based project in Northern Ireland.

Terry Green

Finance Director

Terry is 60 years old, married with 4 adult children.

Current activities include:

- Pursuing, in various parts of the world, the development of my lightweight aggregate from waste technology.

- Working with AU Group on the exploitation of gasifier technology, generating power from waste. The technology will be applied either stand alone or in conjunction with a lightweight aggregate plant.

- Acting as consultant for several clients developing various pelletising processes (glass and paper sludge combustion ash).

1995 to March 2007

Managing Director of a series of companies, which have been working on the technical development of a process for the manufacture of lightweight aggregate from waste materials. Due to lack of funding Terry cannot give any more of his life to this project, on which he has worked since 1990. The work has included:

- Conceptual design, construction and operation of £13m prototype plant mixing sewage cake, ash from a power station and clay to fire in a kiln at 1,200°C to produce aggregate (stone for use in concrete and general construction).

- Negotiating with a substantial Venture capitalist company an option to invest in the rollout of the technology both in the UK and around the world.

- Negotiating a lease and a sludge supply contract with Anglian Water and an ash disposal contract with RWE Npower.

- Responsible for operation of company and re-engineering subsequently undertaken.

- Terry is the named person on the Environment Agency IPPC permit.

- Negotiating a joint venture with RMC group in 1999.

At the invitation of RWE NPower Terry gave a technical presentation to the Ashtec 2006 conference and his paper, “The Manufacture of ‘Designer’ Sintered Aggregate from Waste Materials and Process By-Products” was subsequently published.

1992-1995. Senior Consultant to China Fujian Corporation. Terry was based in the central Hong Kong office of The China Fujian Corporation, which is the commercial arm of the Chinese province of Fujian. He was involved mainly in giving overview advice and guidance of large commercial and residential developments in Hong Kong and throughout Far East, in particularly evaluating start up projects in Vietnam.

Terry was also looking at system build options for World Bank funded social housing schemes in The Philippines.

At this time he was also raising project finance and negotiating with Hong Kong government (successfully) to locate an aggregate pilot plant in Hong Kong.

1989-1993. GDC ltd. Development consultancy. This was a very difficult time for property developers and Terry advised several clients who had to totally re think intended projects including preparation of schemes (full planning and construction drawings) and project management.

1986-1991. Managing Director of Elmgreen Developments Ltd. Newly formed company (of which Terry was also a shareholder) to carry out predominately residential developments in East and South East London. Terry developed a range of schemes, some at very high densities for the time. Schemes included:

- 40 houses + flats in Stratford, East London

- 61 houses + flats + offices units in Surrey Docks

- 40 flats + shops in Deptford

- 21 houses + flats in Plaistow

- 20 flats in Belvedere

All design and sub-contract management carried out in-house.

1983-1986. Technical Director of Barratt East London. Newly formed company within Barratt plc, to work in East London. Very wide scope of work, from first warehouse conversions in Wapping, to social Housing projects. As Technical Director I controlled land acquisition, planning, construction design, sub contractor appointment and payments. From standstill the company tuned over £20m in 2 years (at a time when a warehouse conversion studio sold from £30k).

1972-1983. Head of Planning Department of Reason Homes. Mid sized residential development company operating mainly in Essex and East Anglia (up to 450 units pa). Terry established the drawing office design department covering both architectural and engineering, which employed up to 17 staff. Terry was part of the general management of the company working closely with its directors/owners. During mid 70's he worked with various bank appointed receivers of development companies and advised on redesign, build out and disposal of assets.

Whilst working for Reason Homes Terry designed the first Essex Design Guide scheme built, 200 units, at “The Grove”, Witham.

Prior to 1972 Terry worked for 5 years for a surveyor/estate agent learning multi discipline skills in land survey, planning, civil and structural engineering, then Fairview Estates as regional engineer, then Wimpy as a designer of roads and sewers.

On leaving school Terry started with William Press as trainee engineering draughtsman.

Nicholas P Adams MA, LLB

Company Secretary / Legal

Nick is 58 years old, married with 2 children.

Education:

1960 - 1966 City of London School

1967 - 1971 Emmanuel College, Cambridge (2:1 MA and LLB degrees in law).

Career:

1971 - 1979 Assistant solicitor with Messrs Rowley Ashworth & Co. (London).

1979 - 2002 Partner in various practices in South London with wide experience and expertise in commercial and conveyancing work, litigation and advocacy.

2002 - date Employed or self employed in various projects in Africa (Kenya and Sierra Leone), including several small charitable projects in Kenya, and involvement in a power (Energy from Waste) and employment project in Freetown, Sierra Leone involving negotiations in the high realms of government on behalf of Waishing Investment Ltd, which were successfully concluded.

Ongoing responsibility on behalf of Waishing in connection with all its projects but particularly in the field of renewable energy production.

2005 - date Additionally employed by Kent County Council in the Communities Directorate advancing community cohesion and development in Folkestone.

Other interests: Sport, including coaching, literature, community issues and African matters.

Thomas Anthony Woods (Tony)

Joint Director of Generation

Tony is a family man and is married with 3 children.

A highly motivated, ENGINEER/MANAGER with extensive experience in management of change. Possessing strong leadership skills and a proven track record of innovation and major project work within the power generation industry.

Able to demonstrate commercial awareness in all aspects of the contracting business as seen from the contractor and customer’s point of view.

Having well developed interpersonal and communication skills in all spheres of operation, from industrial relations to contract negotiations.

Key Achievements

- Most recently, have re–organised the RWE npower TSG Ferrybridge Turbine Overhaul Facility, introducing state of the art CNC tooling for the manufacture of turbine blades. Introduced new working practices, customers and capability.

- Project management of a partial refurbishment of Kosovo B2 326 MW Unit. The contract was valued at 20million Euro with a 50/50 split consortium oft Innogy / Alstom. Responsible for Project Management and as site leader of the consortium, resulting in a successful conclusion and achieving programme to time and cost.

- Project managed the refurbishment of 3 x120 MW coal fired boilers and associated boiler house plant at Fifoots Point Power Station. The scope of work included the installation of Low Nox burners with Over Fire Air with Intermediate OFA, and the overhaul of milling plant, fans, valves and all pressure parts. The Project required the development of a strategy for the future management of all headers, steam pipe work and supports whilst completing all Scheme of Examination inspections and repairs in conjunction with the Insurers. On completion of the refurbishment, all plant was commissioned, including a new Automatic Boiler Control system and Burner Management system.

- Managed and developed Hopkinsons Engineering Services (a £8 million division of Hopkinsons Ltd), opening new valve service facilities in Dubai and Aberdeen and procuring the companies first major contract in the Offshore gas and oil industry.

- Extensive mechanical and man management expertise gained in the control of large maintenance departments and contracts at Drax, (Europe’s largest power generating station), Thorpe Marsh and West Burton power stations.

- Production of engineering strategy and technical review for Station Business Plans and in last position, the production of a Business Plan for Hopkinsons Engineering Services.

Career History

August 2003- September 2005 INNOGY plc / RWEnpower

Production Manager TSG Ferrybridge Workshops

Managed and developed workshops, regularly overhauling and modifying Turbine Rotors and associated components up to 660MWs. Developed CNC facility and introduced Blade manufacture for steam and water turbines.

August 2002 – August 2003 INNOGY plc

Project Manager

Involved with the development of various Bio-mass projects including Sewage Waste and Tallow. Appointed Project manager for development and construction of Wood Chip plant at Aberthaw Power Station.

April 2001 – August 2002 INNOGY plc

Project Manager

Involved with preparation and management of 2001 Kosovo B2 Partial Refurbishment Contract. Responsibility included leading the Innogy / Alstom consortium for the 2001 contract which was completed to time and cost. Following 2001 outage, was involved as Site Manager for the Kosovo B2 Follow up contract.

Following the Kosovo B2 project, spent time in Belgrade and UK leading the bid preparation for a major refurbishment in Serbia of Nikola Tesla Unit 3A.

1997 – March 2001 ABB POWER CONSRTUCTION LTD

Project Manager

Project managed the refurbishment of all boiler plant at Fifoots Point Power Station. Developed business in North East and South West Regions, securing new business and clients. Duties include part time involvement as a team member of the Alstom Power “Road Show”, endeavouring to develop new business for the company.

1994 – 97 HOPKINSONS ENGINEERING SERVICES

General Manager

Responsible for valve repair and maintenance division consisting of five regional UK facilities and one Middle East. Involved all aspects of managing a £8million business including business development, budget preparation and control, engineering issues and Industrial relations.

1993 – 94 NATIONAL POWER WEST BURTON

Engineering Services Engineer (Personal Contract)

Responsible for Mechanical Engineering Standards at a 4 x 500 MW coal fired power station. Duties included all major capital schemes and projects. Planned unit outages consisting of two Turnkey Contracts to the value of £12 million. This includes boiler (£4M) and LP turbine (£8M) replant.

Managing team of 4 professional mechanical engineers and a multi-discipline team of 12 engineers and 120 industrial staff during Outage.

Developed and introduced the concept of flexible working teams progressing towards multi-skilled technicians. Introduced a new Quality Assurance policy for boiler tube repairs and opportunity maintenance during break down outages.

1991 – 93 THORPE MARSH POWER STATION

Production Maintenance Engineer (Personal Contract)

Managed maintenance department consisting of mechanical, electrical and instrumentation disciplines through 12 engineers, 130 industrial staff with a £ 3 million budget.

1990 – 91 DRAX POWER STATION

Mechanical Production Engineer (SE)

Responsible for all shift maintenance and major breakdown work on a 6 x 660 MW power station 290 staff £6.4M revenue budget.

1980 – 90

Assistant Mechanical Maintenance Engineer/Mechanical Production Engineer (1E)

150 Shift Maintenance Staff. All plant areas.

1973 – 80

Mechanical Shift Maintenance Engineer.

1972 – 73

Assistant Mechanical Maintenance Engineer.

1972 – 73 MEXBOROUGH POWER STATION

Assistant Mechanical Maintenance Engineer.

1958 – 66 NCB NUMBER 5 AREA DURHAM

Electrical Apprentice and Electrical Fitter.

Qualifications

HNC Electrical and electronic Engineering

HNC Mechanical Engineering

ONC Mining Electrical Engineering

Member of the Institute of Management

Leisure Interests

Sailing, Qualified Yacht Master

RYA Instructor for Shore Based Day Skipper and Off Shore Yacht Master Courses

DIY

Hi-fi

Golf

Simon Williams (Sam)

Project Management

Sam is 40 years old and married with 4 children.

Qualifications

1981 – 1984 Bewdley High School (Worcestershire)

O’ Level: English Language, Mathematics, Physics

GCSE: English Literature, Technical Drawing, Geography, History, Rural Science, Metal Work

Further Education

1986-1989 HNC Mechanical Engineering ~ Kidderminster College.

1990-1991 Computer Aided Draughting (City and Guilds) ~ North East Worcestershire College.

Non Vocational:

2001 Lean Manufacturing - Land Rover Gaydon

Note: Various other work related non vocational courses were undertaken during my career, Product Analytics, Project Synchronisation Studies with Landrover/Jaguar etc.

Career History

June 1988 - November 1989

Steelstock Ltd, Warley.

Steelstock as a Group in its time was the largest supplier of Steel Sheet and Slit Coil in the UK.

Inside Sales Representative with the task of daily cold calling to find new customers and maintain accounts requirements. My area duties also included quoting and estimating – raising orders to transportation arrangements. Products consisting of Hot Rolled, Zinc Coated and Galvanised Steel sold to Major end users, Construction and Engineering Companies.

November 1989 - October 1991

B&G Ventilation Ltd, Kidderminster.

Design manufacturers of Filtration and General Ventilation systems for most Dust and Fume applications.

Design Draughtsman following into Design Development and Drawing to customers requirements. Responsible for each project from the ordering of all parts and equipment required, to the organisation of the installation programs.

October 1991 - March 1995

Neu Engineering Ltd, Halesowen.

Design and Manufacturers of Custom Environmental control Systems.

Sales Support Engineer with the added tasks of Project Management and Design Draughting. Responsible to oversee all contracts, estimating and ordering of all parts - equipment required to complete each Project. All areas of Industry covered from Food to Industrial Engineering, added knowledge of Environmental testing giving a service to suit each customer.

March 1995 - September 1997

Foundry and Technical Liaison Ltd, Willenhall.

Foundry Capital Plant Manufacturer.

Technical Sales Engineer for the South of England, from the West midlands over to south Wales, Anglia down to Kent. Developing new sales potentials, heading two project Engineers~Draughtsmen turning over 1.8 Million over this period based on contracts ranging from 5k to 200k.

I specialised in Technical solutions to meet customer’s needs, designing Systems based on customer’s plans.

September 1997 - April 1999

Disa Technologies Plc & Airmaster Engineering Ltd, Leeds.

UK’s largest Environmental control system suppliers. The immediate parent company being Disa Technologies Plc, which is ultimately owned by the multinational Maersk group of companies. (Shipping Transport and Airlines)

Sales Engineer for the Turnkey Department which yielded 50% of the companies £11.5 million turnover. The main Market is the Foundry and Steel Industry with some involvements with the Cement and Asphalt producers. Contract values between £200k to £1m. Complete control of commercial, pre order discussions to final negotiations.

A good understanding of Aerodynamics and Thermodynamics with Chemistry analysis dependant on which industry I was working at the time.

April 1999 - May 2001

Altek International, Philadelphia, USA

Design Manufacturers of Capital Plant to process Aluminium Dross.

Altek International is a company which markets themselves all around the World, as European Sales Manager it was my responsibility to employ and manage companies to represent Altek. My area included Norway to Turkey and all the countries in between. I would offer training to each of the Agent companies as well as technical support when required. I would be involved in each project liaising with Altek engineering team to final negotiations with the customer and agent. The International Sales Director and I managed the European market, which yielded up to 65% of the company’s overall $18 million Turnover during this period. The remaining 35% was found internationally and was managed by The Commercial Director and three other Sales Managers.

I developed the ability to speak many different languages which was essential to my job.

July 2001 - June 2004

Land Rover, Gaydon

Manufacturers of Prestige Four Wheel Drive and Road based.

Cost Analysis Engineer, working as part of a Team to teach supplying companies to Landrover Group Lean Manufacturing, making these companies more efficient and profitable. This would involve Product Analytics and Project Synchronisation Studies examining each and every aspect of the company in question, from Manufacturing, Shop floor to Delivery methods, effectively taking the company apart and putting it back together in a more efficient form. Also as part of the exercise, any saving would be passed to Landrover group and claimed as part of the yearly budget cost down. Set with £2 million target of savings annually.

June 2004 to Date.

Waishing Investment Limited (Project Management Division)

Responsible for representing Alternative Use Group Plc, where primarily most contracts are Energy from Waste. We also undertake PPC licences and Planning requirements related to these projects offering full service and technical backup overall.

Interests

Motor Sports and General Engineering.

Richard Frearson MBA AMIMechE

Joint Director of Generation

Dick is 49 years old and married with 2 children.

Has 30 years experience in the Power and Environmental sectors, 12 yers as Managing Director of major companies, Member of the Institute of Directors, and Graduate Member of the Institute of Mechanical Engineers.

Qualifications

MBA - University of Derby.

Diploma in Mechanical Engineering – Trent Polytechnic (conversion HND to Degree).

HND Mechanical Engineering.

Profile

A 30 year career in the Power and Environmental Industries has been characterised by rapid personal development. High levels of responsibility have been progressively gained from an exceptionally early age.

In depth training in production control, CPA planning techniques, resource allocation, quality assurance, procurement, industrial relations and client liaison was followed by construction and maintenance experience both in the UK and overseas. A rapid, success based , progression through the higher management levels culminated in the appointment as Managing Director of a Company, which then became the Market Leader in it’s field.

Graduation in 1993 with a Master of Business Administration Degree gave the necessary strategic and business acumen to create a new Company from a standing start. Operating in the global framework of the ABB Group Power and Environmental Segments, the Joint Venture Company grew to achieve a £65 million annual turnover within 5 years using a combined strategy of internal development and acquisition.

Professional Experience

Managing Director, ABB Power Construction Ltd, responsible for all Company Business & Operation (1000+ employees, £65m Turnover).

Managing Director, Dunn International Plc, responsible for all Company Business & Operations (700+ employees, £35m Turnover).

Managing Director, Plant and Consumable Services Ltd (Hire & Sales of Industrial Equipment).

Divisional Manager, Dunn International, responsible for UK Operations reporting to the MD.

Project Manager, Dunn International, responsible for major power and Environmental. Projects of circa £10m in value.

Manager / Engineer, Northern Engineering Industries Group.

Overseas Experience

Mombassa, Kenya - Power Plant Commissioning.

Asalaya, Sudan - Sugar Factory Build.

Venezuela - New Sugar Factory Development.

Germany - Successful Market Entry.

Estonia - Successful Market Entry.

Career Development Phases

Development from Engineer to Manager 1973 - 1984

Progressive Management Experience 1984 - 1990

Year MBA Course 1990 -1993

Development as Managing Director and Strategic Businessman 1990 - 2002

Employment History

Currently engaged in Professional Consultancy.

ABB Group 1994 to 2001

Dunn International 1982 to 1994 and 2002 (now part of the Shaw Group Inc.).

NEI Group 1969 to 1982

Key Skills

Leadership in a 'People Business' culture

Strategic Business Acumen

Communication Skills

Resolute pursuit of Goals

Additional Skills

French, German and Spanish Language Capability - Instrument Rated Pilot.

Designed, managed construction and commissioned gas fired Power Station in Turkey.

Designed, managed construction and commissioned gas fired Power Station in Abu Dhabi.

1990 Roosecote Power Station - Barrow in Furnace

1x ABB 13E Gas turbine - 140MW

1x ABB Steam Turbine - 60 MW

1991 Rye- House Power Station - Hertfordshire

3x Siemens Gas Turbine - 360MW

1x Siemens Steam Turbine - 180 MW

1992 Corby Power Station - Corby

2x EGT Gas Turbines - 400 MW

1992 Brigg Power Station - Humberside

2x EGT Gas Turbines - 400 MW

1994 Medway Power Station - Kent

1x General Electric Steam Turbine - 200 MW

1993 Deeside Power Station - Deeside

2x ABB 13E Gas Turbines - 280 MW

2x ABB Steam Turbines - 60 MW

1996 Killingholme B Power Station

1x ABB 13E Gas turbine - 140MW

1x ABB Steam Turbine - 60 MW

1999 Enfield Power Station

1x ABB GT 26 - Single Shaft Steam and Gas Turbine Unit - 400 MW

1x ABB HRSG

2000 Peterhead Power Station

3x Samsung Heavy Industries HRSGs for 750MW CCGT Re-powering Project

Environmental Power Projects Stoke on Trent Waste to Energy Plant 2x CNIM Incinerators with HRSGs

Flue Gas Desulphurisation Plant - Ratcliffe on Soar Power Station

So3 Injection Plant - Didcot Power Station

So3 Injection Plant - Aberthaw Power Station

So3 Injection Plant - Fiddlers Ferry Power Station

So3 Injection Plant - Ironbrige Power Station

So3 Injection Plant - Longannet Power Station

Steam and Gas Turbine Refurbishments carried out via Consortium Turbine Specialist

Established in the sixties - 40% of the major overhauls and refurbishments on all UK based Steam and Gas Turbine Generating Equipment has been carried out in this facility every year since then. The turbine workshops are equipped with “state of the art” computer controlled blade profiling machines, NDT facilities and rotor balancing equipment. The facility is rated in the industry as one of the best in the world.

|